Internal Scarfing System

Escarfagem / Sistema de Remoção Interna

The Internal Scarfing System removes the inner weld beads of pipes during the manufacturing process.

It is a high-pressure pneumatic tool, which automatically adjusts to the pipe’s inner diameter, even with variations or changes in the plate’s thickness.

We offer technical support and training during the whole inner burr removal pipe manufacturing process (RIR).

We offer technical support and training during the whole inner burr removal pipe manufacturing process (RIR).

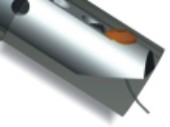

The image at the side illustrates the inner weld removal moment and the splinter exit.

Support Plate and Adjustment

Suspension / Suspensão

The Support Plate is fixed at the closest point possible before the Weld Guide and its size varies in accordance with each preparation. Its job is to support the rod and enable the necessary adjustments and location of the Tool with the weld bead, which will be removed.

Fixing the Weld Guide at the closest possible point, allows for a reduced Support Rod length. This in turn offers better scarfing stability.

Support Rod with Impeder

Tube Penetration with Impeder / Varão de Sustentação

The support rod is inserted in the pipe, which is being formed, through an orifice prior to its closure with roll spot welding. The fixing on the Support Plate, positions the Impeder r at the ideal point for the pipe welding.

There are entry orifices for refrigeration fluids and pneumatic pressure in the Rod and plate coupling. The refrigeration fluid must be under high pressure and filtered in order to obtain sufficient outflow to refrigerate the ferrite.

The best ferrite efficiency is obtained by using a sufficient volume of clean and refrigerated fluid, thus avoiding excessive electric power consumption during the welding process.

The system enables the rod length to be reduced in order to obtain stability and rigidity when removing the weld beads.

Benefits

- Increase in performance and improvement in the weld quality.

- Constant tool stability through pneumatic pressure on the cutting ring.

- Cut depth correction as the cutting ring can be adjusted to the weld line.

- Easy substitution of the cutting ring.

- Reliable orientation thanks to a rigid coupling.

- The refrigeration of the cutting ring is an additional benefit. This characteristic prevents material accumulating around the cutting ring while the cutting is carried out.

Click here and view our tools.